Lift, Press, and Tighten with Controlled Precision

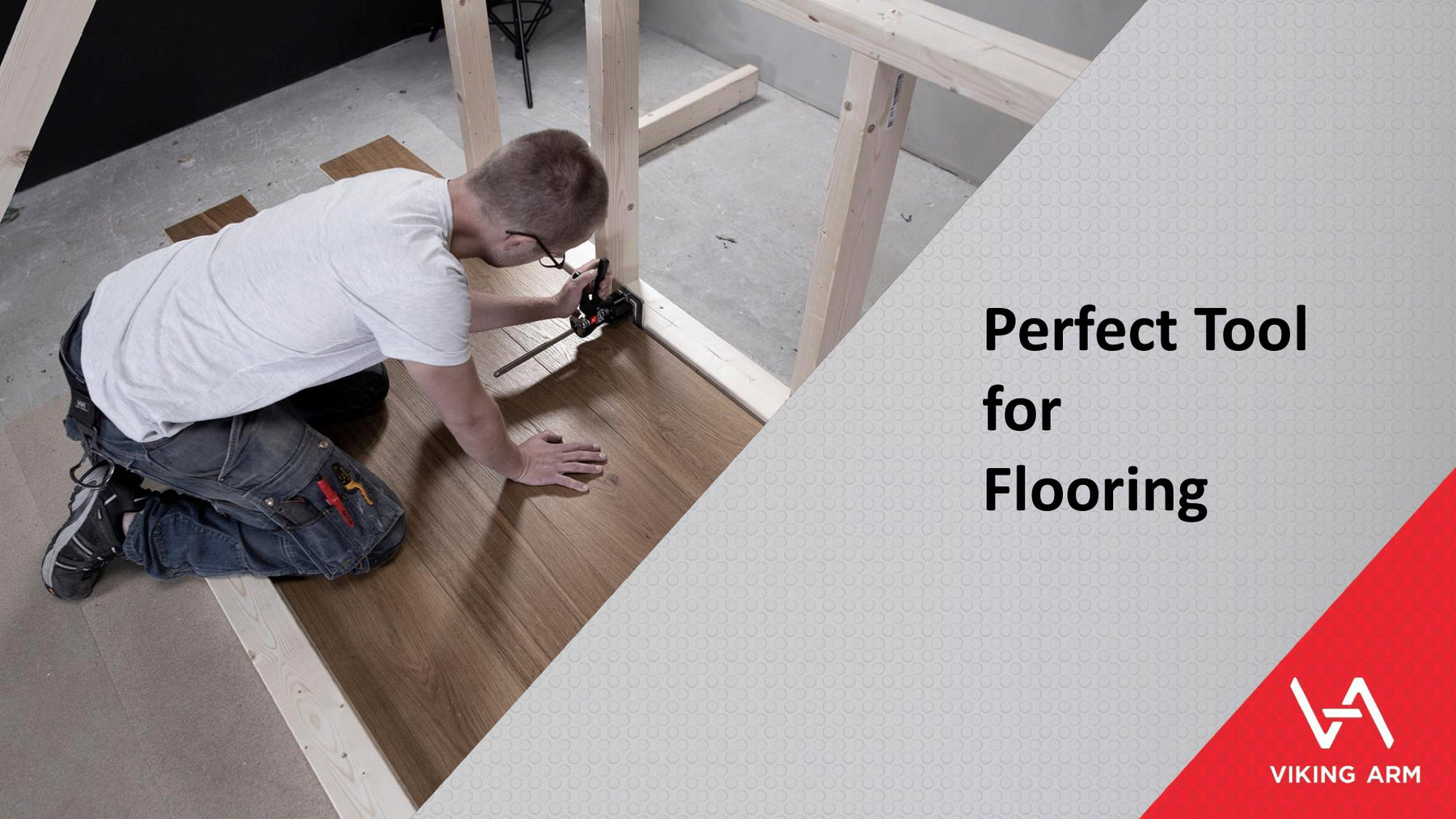

The Viking Arm is a Workhorse Hand Lift for Tight Spots.

These Norwegian-made hand jacks are a premium product. The Viking Arm was designed as a construction industry tool, used for supporting and holding large panels and cabinetry in place during cutting, drilling, and installation. It can also be reversed and used to squeeze things together, like floorboards or heavy joists. It’s commonly used in a variety of woodworking, metalworking, and construction projects.

But as Museum pros have learned (Peeps like Rob Kimberly) that the tool extends beyond the construction site. Think of the crates that are too low for the pallet jack or big sculptures that need to come up just 5″ to make it onto a riser. Don’t get me wrong, it’s super useful in the shop, but the utility doesn’t stop there for us.

Your imagination sets the limits

With a lifting capacity of up to 150kg/330lb, the range of applications is virtually unlimited. The installation of doors, windows, cabinets, and kitchen appliances are obvious uses. Additionally, the construction of porches, decks, flooring, and foundations are perfect opportunities to implement this ingenious tool. All this and much more can easily be achieved with controlled precision thanks to the unique construction of the VIKING ARM® tool.

Enhance productivity

Another great feature of the VIKING ARM® is that it reduces the number of hands required for installation work. Significantly enhancing efficiency for professionals in addition to reducing frustration among home improvers. Most importantly it saves time, money and your…back!

The VIKING ARM® – A Professional Tool for All.

Shipping Information

Free Shipping – Lead time is 2-6 business days. Faster service available upon request. Write me at [email protected], I’ll get it you!

International shipping available, shipping fees and duties not included in product price.

FEATURES

- Innovative universal tool

- Lift, press, tighten with precision and control

- Impressive capacity for a compact hand tool

- Patented technical solutions

- May substitute multiple “traditional” tools

- Inspires creativity, secures quality and safety

- Increases productivity, saves time and money

- Sturdy and durable construction

- Components of the highest quality

- Designed and manufactured in Norway

SPECIFICATIONS

- Hardened stainless steel / Aluminum

- Capacity: up to 150 kg = 330 lb

- Operation range (mm): 6-215

- Standard base (mm): 5 x 105 x 87

- Optional base in hardened carbon steel (mm): 6 x 105 x 87

- Optional base (mm): 3 x 77 x 62

- Mounting holes for safe operations

- Weight: 1,4 kg = 3,0 lb

- Extensively tested by FIMTECH (Norway)

Are you still not in love with this tool?

WAIT, did you go looking to find something like the Viking Arm only cheaper? There are many videos exploring “the other guys”. There’s literally no comparison, save yourself the money and buy this Viking Arm today. This tool will be with you for years to come:

Frequently Asked Questions

HOW HEAVY AN OBJECT CAN BE LIFTED BY VIKING ARM?

Lifting an object weighing up to 150 kg (330lbs) with one Viking Arm equipped with optional 6 mm thick baseplates and bars (standard today is 5 mm) should not be a problem. Lifting of heavier objects is not covered by the product warranty. Please see maximum load diagrams in the Manual & Tutorials section.

HOW HIGH CAN THE VIKING ARM LIFT?

The Viking Arm has a lifting range of 6 to 215mm (0.24″ to 8.46″)

WHERE IS THE VIKING ARM MADE?

The Viking Arm is made in Norway.

WHERE CAN I FIND THE VIKING ARM MANUAL?

You can find the Viking Arm user manual HERE and instructional videos HERE.

DO YOU OFFER A PRODUCT WARRANTY?

Yes! Warranty claims must be submitted to MuseumTrade in writing within sixty (60) days from the time the defect is, or should have been, discovered. For two (2) years from the date of purchase, Viking Arm is warranted for the original purchaser to be free from defects in material and workmanship.

Exclusion of liability:

- Claims will be rejected if failure is due to abuse, incorrect use, impact damage, negligence, accident, alteration, normal wear, or lack of proper recommended maintenance, including the use of parts not approved by Viking Arm AS.

- Damage resulting from overloading the product.

- Failure due to chemical corrosion and physical erosion.

- Work performed by repairers not approved by the Company.

- Unauthorized alteration.

- Failure caused by theft, or vandalism.

- Loss of time, loss of use of the product, or any other loss that may result as a consequence of failure.

Viking Arm will always be useful to you, provided you take good care of the tool like protecting against damage and rust and storing it neatly. Please carefully read our maintenance and safety tips in the Support section.

All warranty claims must be made and addressed to [email protected]

I HAVE BENT LIFTING BARS. WHAT CAN I DO?

Lifting an object weighing over 150 kg with one Viking Arm may result in bent bars/base. Such use of the tool is not covered by our product warranty. You may remove the bars/base and try to bend them back. If this doesn’t help, you can replace the bars/base. Please send me a message if you need to order spare parts.

MY VIKING ARM MAKES A CREAKING NOISE. CAN I FIX IT SOMEHOW?

While creaking can be really annoying it doesn’t affect the Viking Arm’s functionality. Actually, some craftsmen prefer to work with a “dry” tool. If you want to eliminate creaking, you may try to twist the springs a bit first. If this doesn’t help, any quality technical lubricant will fix

HOW SHOULD I MAINTAIN VIKING ARM? CAN I REPAIR IT IF I EXPERIENCE ANY PROBLEMS?

It is important to maintain your Viking Arm regularly. This will help increase the service life as well as the performance.

Your Viking Arm should remain free of debris, sand, cement, and dust, which can cause damage over a long time. It is well worth spending a few minutes cleaning the tool compared to the cost of repairing or replacing it.

Cleaning the tool regularly is essential to its proper functioning. You can clean it by simply wiping it all over with a rag. If the arm is dirty, do not hesitate to disassemble it, clean and lubricate all the parts properly. Please watch our Viking Arm Assembly video in the Manual & Tutorial section.

Lubricate your Viking Arm before you start using it and on a regular basis after that. Sprinkle metal parts with a light coat of any good industrial lubrication oil. Lubricating helps to improve the performance of the tool, solve occasional loss of functionality, reduce wear and tear of components, and prevent corrosion.

Regularly inspect your Viking Arm for signs of damage and faulty functioning. Ensure that you repair your tool immediately if there is any damage.

Reviews

There are no reviews yet.